Sailmaking today is an intricate art. Sails are made of a wide variety of materials, some of them woven fabrics, others laminated films and many also combining both types. So let’s find out what is the best sailcloth for cruising sails.

Sail design not only depends on the type of sail and its intended use, be it offshore cruising, family sailing or competitive club racing, but also on the sailcloth. And there is not one type of sailcloth that is best suited for all sails. Some are more all-rounders than others, but each is designed for a specific type of use. Racing sails are made for maximum performance, while cruising sails are made to last for thousands of miles.

So, let us get under the skin of our sails and take a close look at the sailcloth’s chosen by Rolly Tasker Sails and why we use which sailcloth for what kind of sail. Always in accordance with our credo in sailmaking, to offer the best value for money. And if someone demands the best of the best, regardless of cost – well, we can deliver that, too.

Woven sailcloth and cruising laminates

The vast majority of cruising sails are made from woven polyester sailcloth. This is commonly known as Dacron sailcloth, with Dacron being the trade name for the special polyester yarn that this type of sailcloth is being woven from by the sailcloth manufacturers. The lengthwise threads are known as the “warp”, which are held together by threads that are passed back and forth through the warp, known as the “weft” or “fill”. The strength of a sailcloth is determined by the strength of the threads is it woven with, but also from the way it is woven. The weight of the sailcloth depends on the thickness of the treads, but also on their number.

A small number of thicker threads can lead to the same cloth weight as a larger number of thinner threads. Another factor is the density of the sailcloth, which depends on how tight the threads are driven together. As we can already see without diving too deep into the matter, the exact design and weave of sailcloth’s is complex, which each manufacturer developing their own cloths.

At Rolly Tasker Sails, we use highly sophisticated Dacron from leading sailcloth suppliers such As Challenge, Contender or Dimension Polyant to make our cruising sails, for inshore, coastal and offshore sailing. For the family or cruising sailor, Dacron offers the best value for money. It is easily handled, as it is softer than the typical laminate. It can be very easily furled and folded and also stowed away in a sail bag. The perfect, uncomplicated sail for average, day-to-day use.

Cruising laminated sails are made of unwoven films of various materials, bonded together with fibers like Polyester, Mylar, Kevlar or Dyneema. Each of these has specific characteristics and the laminate is designed as a combination of materials to achieve the best possible shape-holding proportion or other desirable qualities such as low weight or high tear resistance. Sandwich laminates can also be made from a combination of films and woven materials. The design of these cruising laminates is even more sophisticated than that of woven polyester sails.

Which sailcloth should I choose for my sails?

The expert sail designers and sailmakers at Rolly Tasker Sails will guide you towards the best solution for your specific needs in sails. However, an understanding of the basic characteristics of any given sailcloth will help you to consider the available options even better. Below, we explain the different materials that we use to make different types of upwind sails.

Newport Dacron Crosscut by Challenge Sailcloth

For example, the “Newport” allround cruising Dacron by Challenge Sailcloth is probably the best value for money sailcloth available on the market today and thus ideal for the cruising range of Dacron crosscut sails by Rolly Tasker Sails. For inshore, coastal and offshore use. It is made of a high-shrinking polyester yarn developed by the R&D team at Challenge Sailcloth in a collaborative effort with leading fiber manufacturers and textile engineers. This yarn makes the most densely woven fabrics, with the greatest quantity of fiber interlockings.

Sails made from Dacron are best for all-purpose family or cruising sails.

Newport ProRadial Dacron by Challenge Sailcloth

The sailcloth “Newport ProRadial” by Challenge Sailcloth is a woven Dacron specially designed for radial cut sails. Fine fibers make for a tight weave and a more delicate cloth. The results are good shape holding, rugged durability and high UV protection. This cloth can best be used for yachts of up to 45 feet.

With seams in load direction, these sails have more of a technical look, as opposed to a cross cut. Good for slightly more ambitious sailors or if you just want your boat to look good with more modern sails.

Fastnet Dacron by Challenge Sailcloth

“Fastnet” Dacron by Challenge Sailcloth is a special Dacron sailcloth that was originally designed for the very tough “Clipper Round The World Race”. For ocean sailing under harsh conditions, this sailcloth must be extra strong and made to last under even the worst conditions, also with a higher than average UV resilience. In effect “Fastnet” has to be “overbuilt”, to be more durable and stronger than other sailcloths. The “Fastnet” sailcloth is made for offshore sailors who need bulletproof durability and UV resistance.

This sailcloth is highly abrasion resistant, cut and tear resistant and UV resistant.

Fibercon Pro Hybrid by Contender Sailcloth

Our top-shelf product at Rolly Tasker Sails for the high-end cruising sailor. Specially designed for the bluewater adventurer, this sailcloth is so strong and durable that it provides a high sense of safety. The sailcloth is made for radial cut sails for yachts from 32 to 65 foot in length.

“Fibercon Bro Hybrid” is a hybrid material where polyester yarns are woven together with UPE yarns – “Ultra high molecular weight Polyethylene”. Examples of UPE would be Dyneema or Spectra, but these are brand names.

UPE is not affected by UV, very difficult to break and has great flex strength. It is however very difficult to bond, which is why Contender Sailcloth weaves it in with Polyester, avoiding the need for lamination of any kind.

“Fibercon Pro Hybrid” will be difficult to tear. Even if, for example, a batten might break and puncture the cloth, it will not tear any further from there. Due to its characteristics, a lighter fabric can be chosen for a bigger boat. As for the handling, the material will be slightly stiffer than others – but on the size of boats for which it is best suited, the sails will be left on the furling stays and the boom and not taken off after sailing.

“CDX Pro” by Contender Sailcloth

“CDX Pro” by Contender Sailcloth is the Rolly Tasker Sails Cruising Laminate. These are for radial oriented sails on a performance cruiser or club racer from 28 to 50 feet. Cruising laminates have a very good stretch result for the weight.

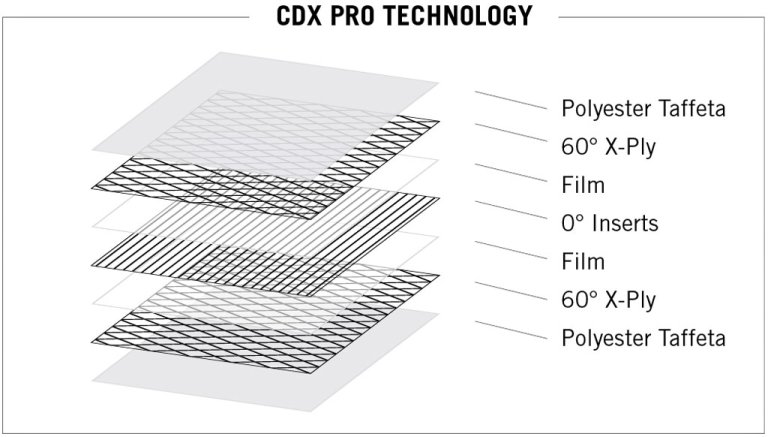

“CDX Pro” It is made from a range of polyester base laminates using Taffeta on both sides, with insertion of some Polyester in the warp and cross-ply axis, which means there is not only one yarn, but two cross-crossing the warp. The fiber content is loaded through the warp into the Taffetas. Duncan Skinner of Contender Sailcloth explains it this way:

“We take a film, and we laminate the Taffeta and the axe to the film and then, depending on what we are making, we can take one of these sub-assemblies, put glue on either side of that, introduce the warp and laminate it together. There are a total of five glue lines in each of these products, which give excellent bond strength. This is a hugely popular range. The price is higher than Dacron, as there are more steps involved in making the material, but you do get a lot more warp strength.”

This robust material is very chafe-resistant and durable, the sails are shapeholding and smooth in handling. UV resistance is also good and a robust anti-mildew additive provides advanced protection against mildew.

“Lite Skin” club racing sails by Dimension-Polyant

“Lite Skin” is made by Dimension-Polyant. For Rolly Tasker Sails, Dimension-Polyant manufactures two laminated fabrics with “Lite Skin”. One with an inner layer of Polyester, designed for smaller boats of up to 30 feet, and another one with Aramid inside for larger yachts up to 38 feet.

“Lite Skin” is a special surface material laminated to the outer skin. It is a thin film of non-woven Polyester treated with coatings and processed in a special way, designed not to create lasting crease folds that lead to film shrinking of laminated sails. “Lite Skin” sails will remain smooth and relative crease-free. To match best price to value, it is designed for cross-cut sails.

“Lite Skin” is made for sailors who want the good shape of a laminated sail, but who also want their sail to keep that shape for a long time. Lite Skin offers an attractive alternative to the keen sailor that wants a performance cruising or club racing sail with a hint of racing heritage.